Is Your Artificial Grass Melting? The Cause And The Solution

Artificial Turf Melting: The Cause & The Solution

It’s becoming an increasingly common problem for many homeowners.

If you are finding streaks of your turf melted and discolored, the culprit is most likely a nearby window that has something called low-e glass in it.

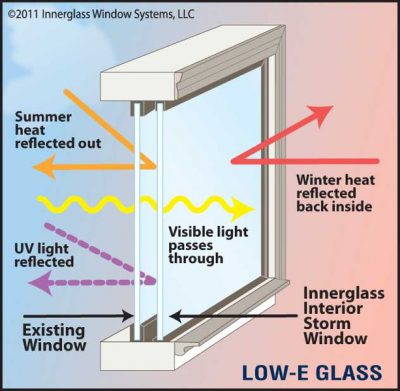

Illustration of how low-e glass windows work.

Low-e glass is glass that has been treated with a type of energy-efficient coating. The glass is coated with a microscopic, transparent metallic layer that reflects heat, but still allows light to pass through.

These windows are good at cutting down the amount of heat entering a house, which is why more and more homes are being built with them installed. However, they can also act like a giant magnifying glass.

Low-e windows are all double-paned, and when there is a difference in pressure between the outside air and the interior of the glass panes, the windows may slightly warp and bend. This can create a concave effect in the glass.

This concave effect, coupled with the reflective Low-E coating, can focus sunlight into a concentrated hot spot, just like you see with a magnifying glass.

The temperature of these hot spots can get so high that they destroy anything they touch.

It’s increasingly common for these Low-E windows to melt synthetic turf, vinyl siding and even cause natural grass to catch fire.

Fake grass will begin to melt at around 175 degrees Fahrenheit. We recently had a customer write to us to say that his turf was melting due to a Low-E window. He took a reading of the hot spot that was destroying his lawn and it was over 190 degrees.

If a large enough patch of turf has been melted, it will need to be replaced. Since artificial turf can cost anywhere from 5 – 25 dollars a square foot (not including labor), replacing damaged turf is a costly and time-consuming process.

EZ Snap customer with a hot spot on his lawn that was over 190°F.

As more and more homes are getting Low-E windows installed, so are the number of people finding their turf being damaged. Even if you don’t have Low-E windows your lawn may still get scorched.

If you are seeing signs of damage to your turf and don’t have Low-E windows on your house, the cause may be one of your neighbor’s windows.

What can be done about Melting Turf?

First, know that if you take the time and money to replace your lawn but don’t address the cause, it’s just going to happen again.

A simple solution would be to put something up, such as a patio umbrella, to protect your turf. This would only be a temporary fix though because anything you put in the way of the hot spot will only get destroyed.

What needs to happen is for the sun’s rays to be blocked before they can hit the window and reflect back out. If the solar heat is cut down before it ever touches the glass, then there is nothing to reflect out and your lawn is safe.

Fortunately, EZ Snap Shade Screens are the ideal solution. They can be installed right over the problematic Low-E glass window quickly and easily and for a lot less than it would cost to replace the entire window.

View from a window with EZ Snap Shade Screen.

EZ Snap Shade Screens are proven to stop up to 90% of the sun’s rays from reaching the glass. You get all of the cooling power of a Low-E window, but without the risk of creating hot spots.

They are easy to order and can be installed by someone with no previous experience.

One of the reasons why Low-E glass is so popular is that it blocks the heat while still allowing light to shine through. What’s great about EZ Snap is that it uses an optical grade mesh, meaning EZ Snap blocks the heat but not the view. The screens are also guaranteed to fit all window sizes and shapes.

To learn more about EZ Snap and its benefits, click here.