How can we help you?

-

Window Shades

-

Skylight Shades

-

RV Shades

-

Yacht Shades

- Articles coming soon

The 3M adhesive that has been developed for the EZ Snap stud has extreme holding power when properly bonded. This amazing adhesive also features the ability to substantially flex and stretch before it ultimately fails when put under a massive pulling force.

When correctly installed on an EZ Snap window shade or RV Skirting kit, they require an extreme amount of force to remove.

In this video, the stud was intentionally failed and pulled apart to demonstrate not only the holding power of the adhesive but also what a properly bonded EZ Snap stud looks like.

The pulling force was also intentionally applied to one side to make it easier to fail the adhesive. If we would have pulled straight out on this stud, it would have been very difficult to fail the stud.

It is the strength of this adhesive that allows the EZ Snap adhesive to stand up to extreme winds and forces. The key though is to properly follow the installation instructions to achieve a proper bond.

Surface Prep for 3M Adhesive Studs:

Important: When installing using the EZ Snap adhesive studs, the surface must be cleaned with isopropyl alcohol ( ideally a 70% isopropyl and 30% water solution). This will help remove any oxidization or contaminants.

3M also recommends using the 3M Primer on the mounting surface where the adhesive will be adhered to.

The mounting surface must be a minimum 1 inch wide, totally smooth, flat, and clean.

Peel & Stick 3M:

Once you have cleaned and primed the mounting surface for the adhesive studs, simply peel off the liner on the back of the stud. Take care not to touch the adhesive once the liner is removed as this can contaminate the adhesive surface.

Press Hard:

Press the adhesive studs into place on the cleaned and primed mounting surface. Press and hold the adhesive studs in place with firm pressure for a few seconds. 3M recommends 15 lbs of force. Press in the center and around the outer edges.

Installation Temperature:

Ideally, temperatures should be at least +15 C / 60 F during installation and for 72 hours continuously. It is recommended to let the adhesive studs set a minimum of 24 hours before you start to install the EZ Snap material.

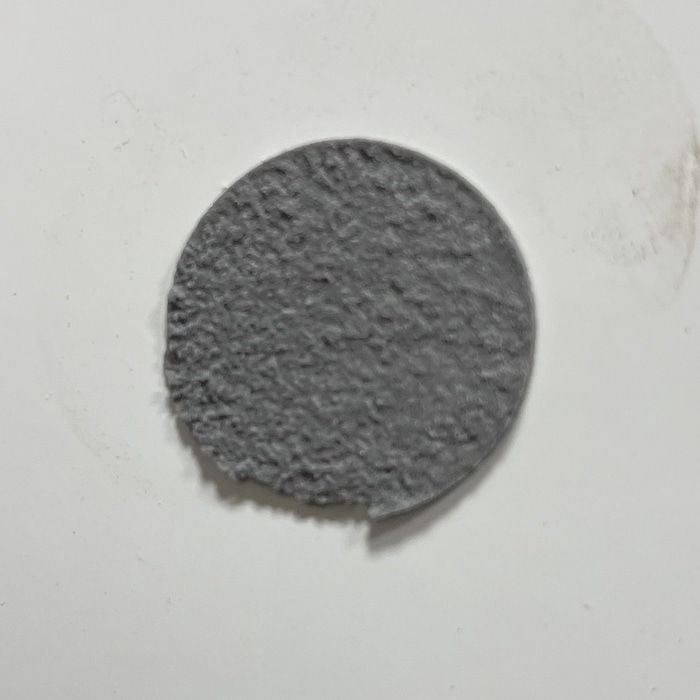

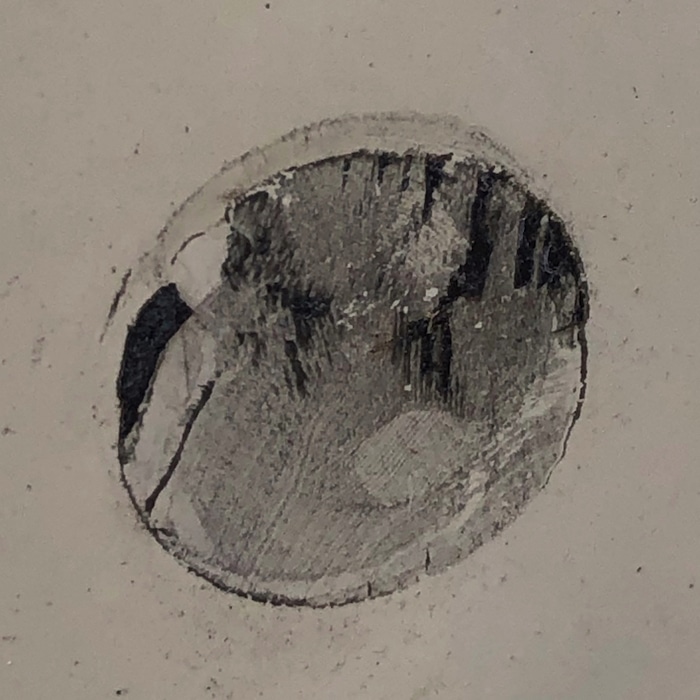

When EZ Snap 3M Adhesive Studs are pulled off of the mounting surface, it is easy to see how strong (or weak) the original bond was. The difference is obvious, as shown in these photos…

3M Adhesive Good Bond Pattern

3M Adhesive Poor Bond Pattern